PDLC Technolog (Polymer Dispersed Liquid Crystal)

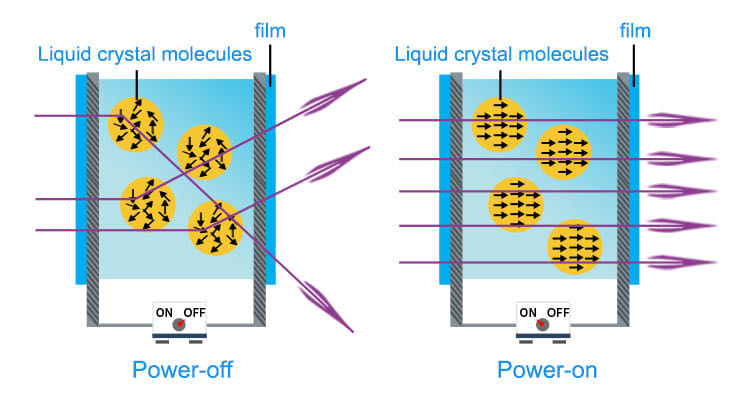

How PDLC Technology Works

PDLC is an active smart technology meaning it needs electricity to turn on and off. When a low voltage is applied (the ON state), the molecules align into a formed manner, allowing light to pass straight through, and making the glass transparent. As electricity is turned off, the LC molecules scatter randomly again, breaking the passage of light and turning the glass opaque.

PDLC Technology Products

PDLC Technology Products

Self adhesive Magic Film for Existing Glass

Non adhesive Magic Film for Smart Glass Lamination

Laminated Smart Glass

Insulated Smart Glass (IGU Smart Glass)

Other special glass with PDLC Film composite products

Applications of PDLC Technology:

PDLC technology finds versatile applications, from windows and partitions to high-tech displays. It’s a favorite in environments where on-demand privacy control is paramount, such as meeting rooms, hospitals, and residential spaces. The ability to customize transparency levels and integrate interactive features makes PDLC a go-to solution for those seeking dynamic and adaptable smart glass.

Suspended Particle Device (SPD) technology.

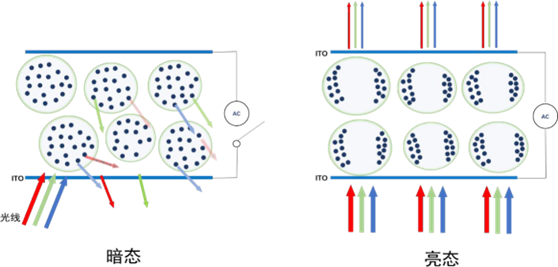

How SPD Technology Works

SPD contains miniscule solid particles which are suspended in liquid and coated between two thin layers of PET-ITO to create a film. It shades and cools interiors, blocking up to 99% of incoming natural or artificial light within seconds of shifting voltage.

Like PDLC, SPD can be dimmed, allowing for a customized shading experience. Unlike PDLC, SPD does not turn completely opaque, and therefore, is not suited for privacy, nor is it optimized for projection.

SPD is ideal for exterior, sky or water facing windows and can be used in indoor applications as well, where darkness is required. SPD is manufactured by only two companies in the world.

Applications of SPD Technology

SPD smart glass is commonly used in automotive sunroofs, windows, and skylights. Its ability to quickly adjust tint levels provides glare control and enhances comfort for occupants. While it shares the goal of offering privacy on demand, SPD technology may excel in settings where rapid transitions between transparency and opacity are essential.

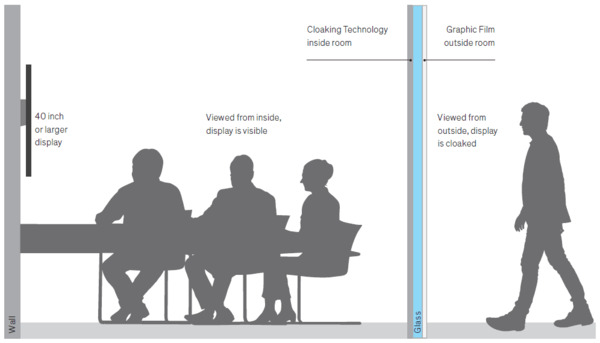

Nano Cloaking Film Technology

How Nano Claking Film Technology Works

Nano Cloaking Film is an LED cloaking technology for glass walls that obscures content on LED screens from outside view. It’s a high transparent film material with back adhesion which can be easily pasted on the glass. Anyone looking into the room from the outside sees just a black screen, while everyone in the room can work freely with peace of mind.

Supported Display Screens

✔LED Backlight Liquid Crystal Display(Majority)

Not Supported Display Screens

✘Surface Hubs and Collaborative Touch Screen Devices;

✘OLED displays, Laptops, Tablets, Smart Phones;

✘Projection Displays, Displays Mounted Behind Glass;

✘Plasma Displays, Passive 3D Displays, CRT Displays;

Transparent LED Film Technology

How Transparent LED Film Technology Works

Transparent LED Film display is a new type of display technology, which has the characteristics of high transparency, bright colors, and high brightness.

Invisible PCB or Mesh technology comes with up to 95% transparency and at the same time offers full display properties.

At first glance, you do not see any wires between the LED modules. When the LED film is off, the transparency is almost perfect.

It can be simply adhered onto Window displays an innovative way to provide eye-catching digital content onto a window display without blocking the visibility inside the retail store.

There are numerous LED pitches options of 2.5mm, 3.91mm or 6.25mm, with different brightness options suitable for various installation locations. (The higher the pitch, the lower the resolution and the higher the transparency).

The panels can be seamlessly joined together to fit a larger area, or panels can also be cut down to the required size.

The panels can be simply adhered to the glass using a sponge, so installation is simple .

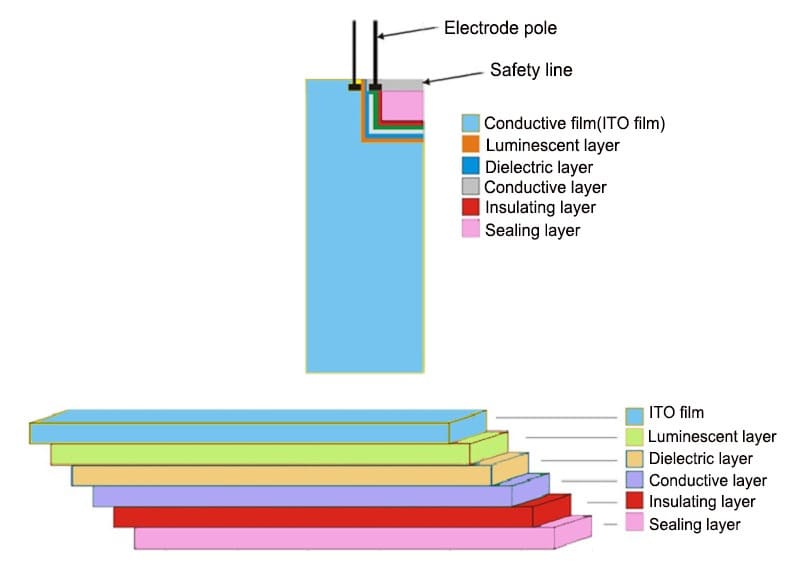

Electroluminescent (EL) Panels Technology

How Electroluminescent (EL) Panels Technology Works

EL Panel (Electroluminescent Panel) technology refers to a type of lighting or display technology that uses electroluminescence to produce light. Electroluminescence is the phenomenon where a material emits light in response to an electric current or a strong electric field.

Structure:

EL panels consist of a phosphor layer sandwiched between two conductive layers (electrodes).

One of the electrodes is typically transparent (e.g., indium tin oxide) to allow light to pass through.

An alternating current (AC) is applied to the electrodes, causing the phosphor to emit light.When an AC voltage is applied, the phosphor particles in the panel are excited and emit light.

The color of the light depends on the type of phosphor material used.

EL panel technology is valued for its unique properties, particularly in applications where flexibility, uniformity, and low power consumption are critical. However, it is less commonly used in high-brightness or high-resolution applications compared to LED or OLED technologies.